Description

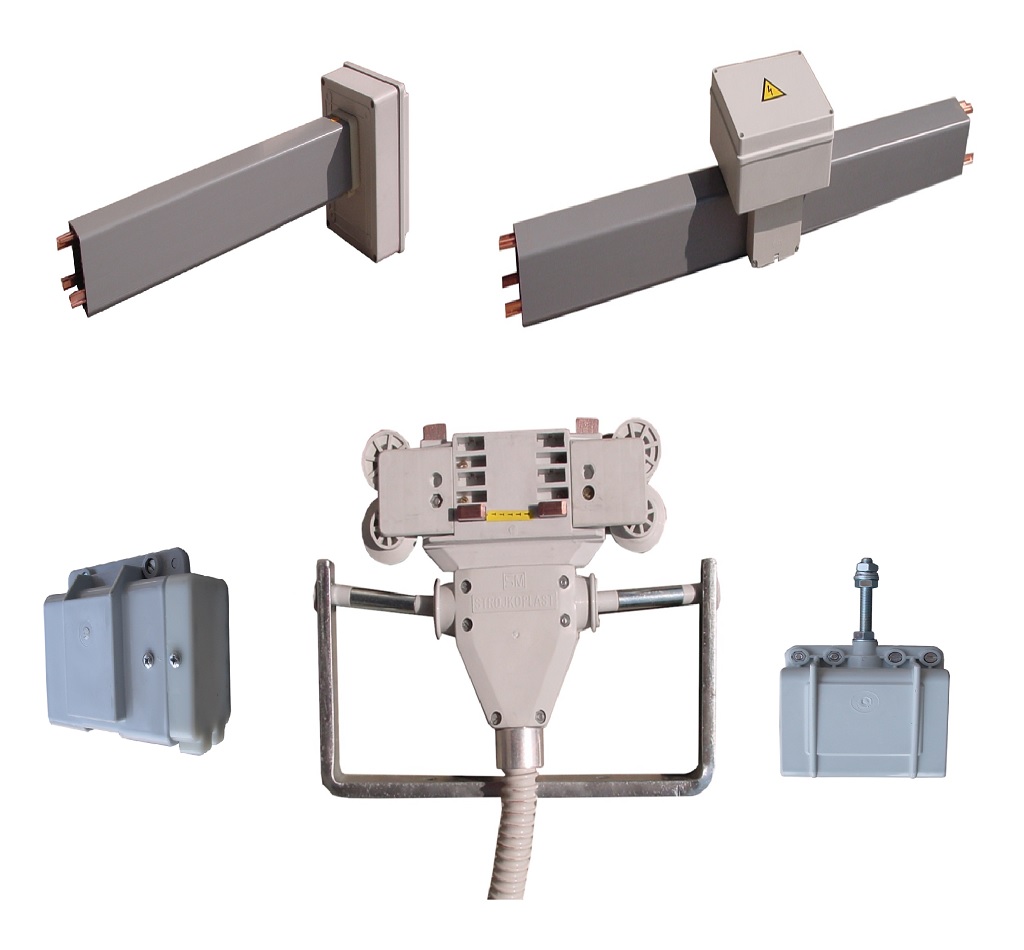

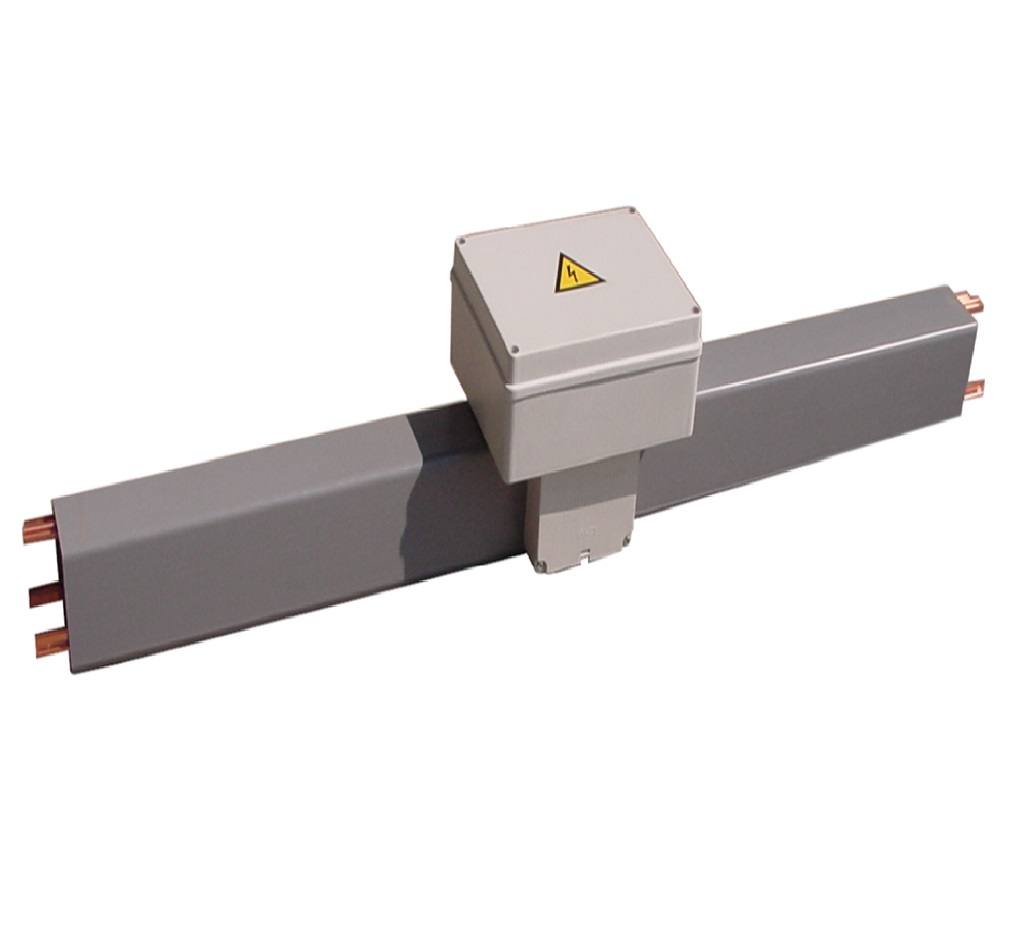

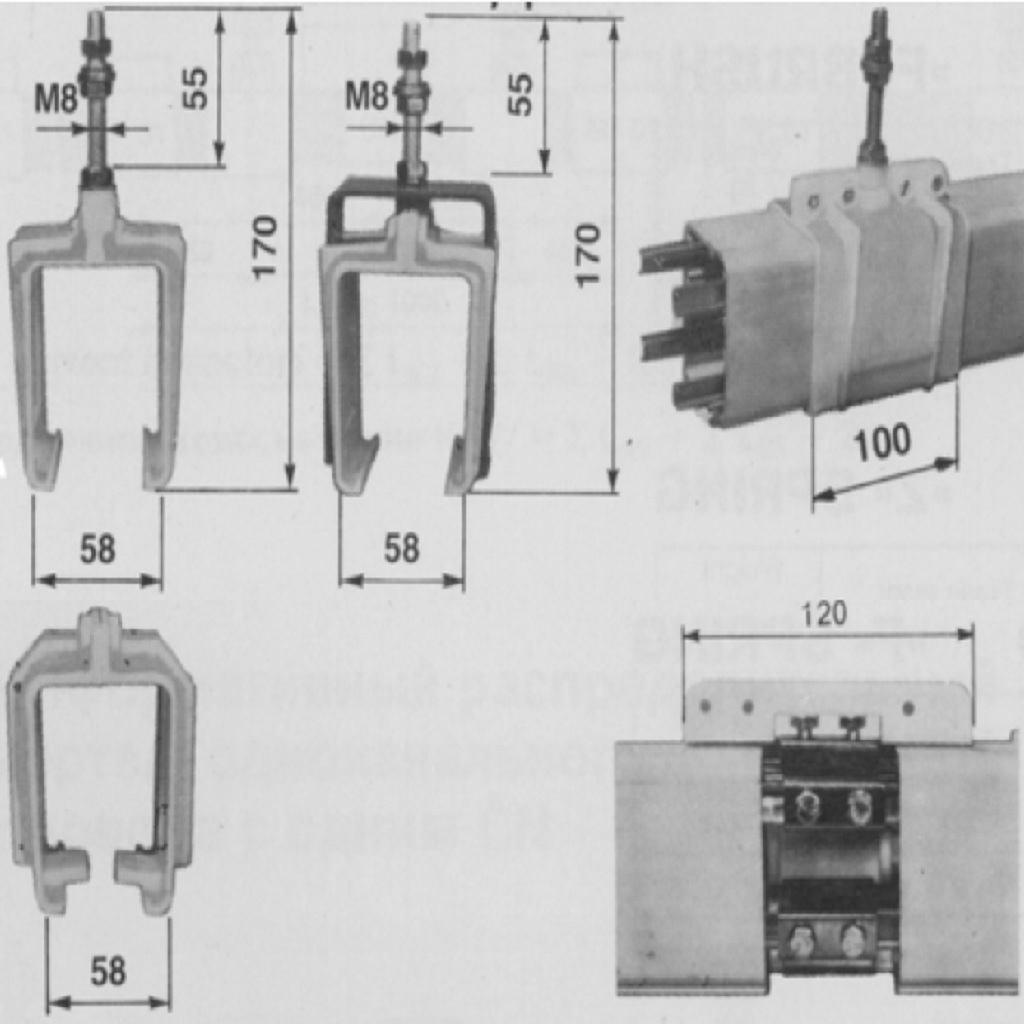

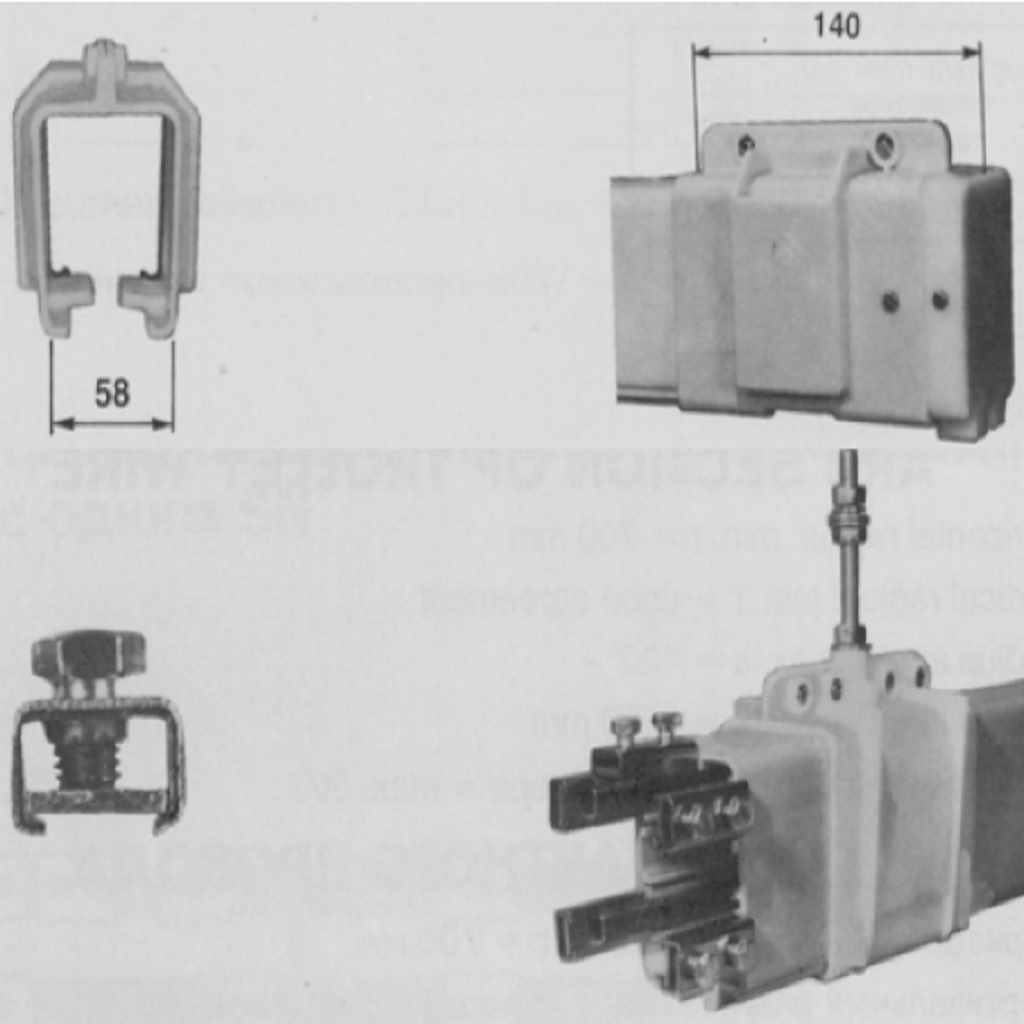

The trolly wire consists of an extruded housing made of an insulating material, with an opening on the bottom, where copper conductors are inserted in order to ensure continuous power to one or more consumers.

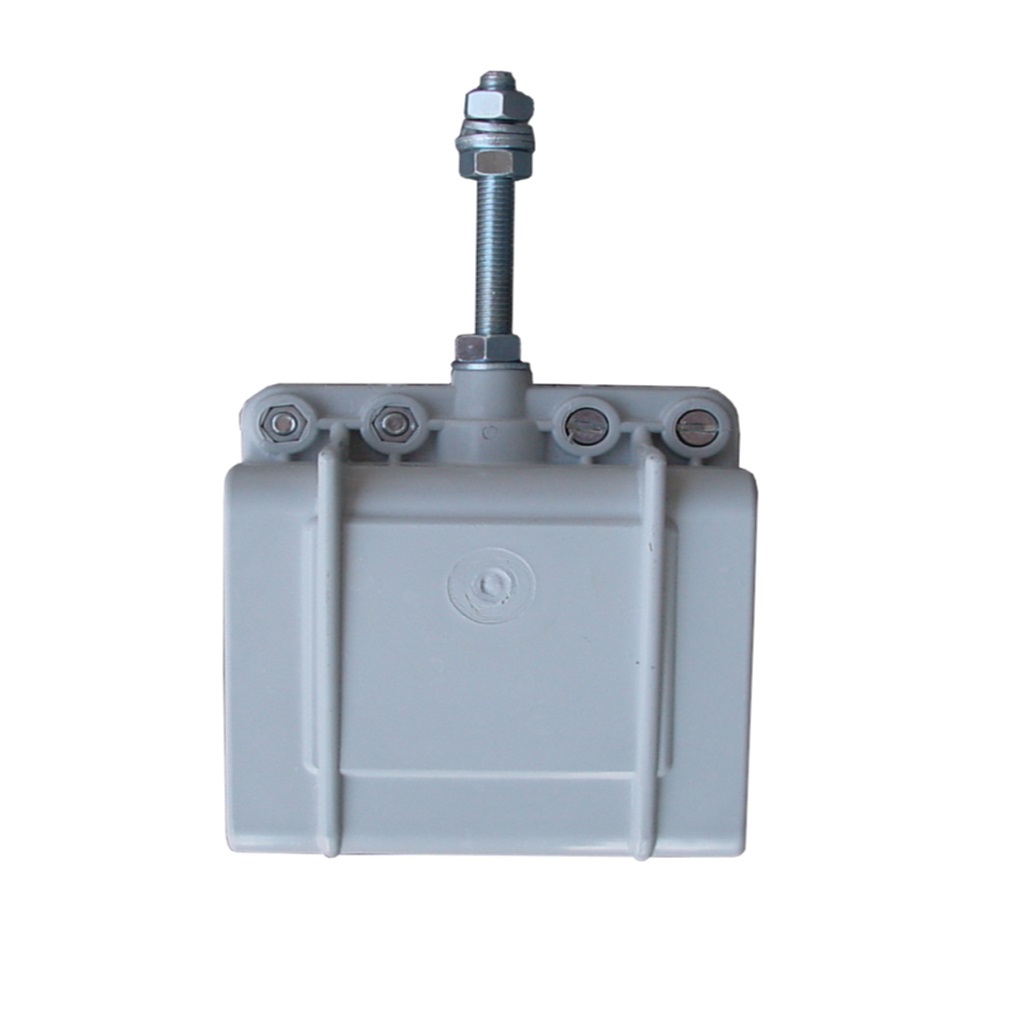

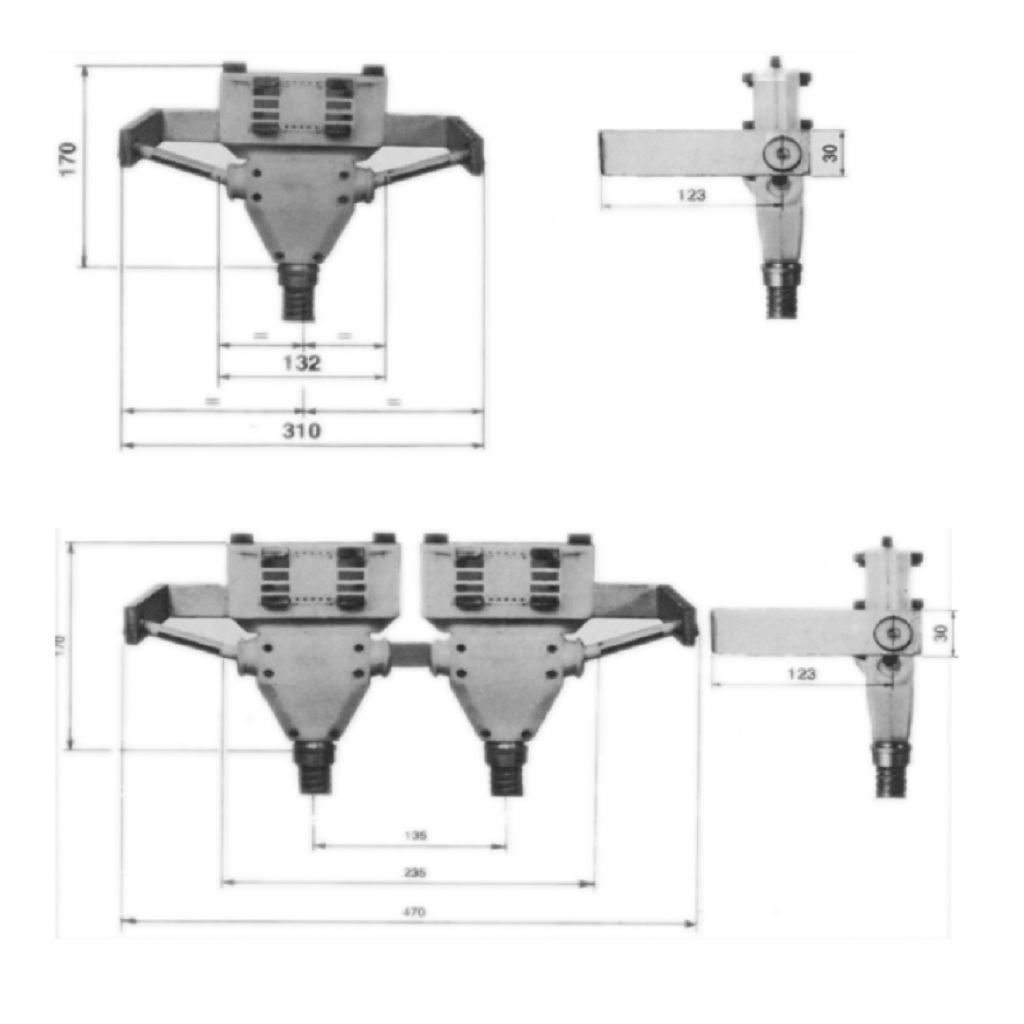

The electrical current is conducted through the current collector (graphite brush and stranded wire, mounted in a flexible hose) into the distribution box. The housing is mounted on the surface (celling or other parts) with suspension stirrups along the entire length of the trolley wire. The standard length of a straight section is 4 m, of a central feeder 1 m and of a front feeder 0,5 m.

Technical data

The rated moving speed of a current collector is 80 m/min. A higher continuous moving speed can result in a quicker wear and therefor a decreased service life. The required traction force is a minimum of 8 N in the direction of the movement, under an angle of 45 ° (x-y space).

The rated cross section and electrical current of a single copper conductor are 20 mm ² and 80 A (per phase conductor).

The whole trolly wire system is made of a hard PVC material (resistant to mineral oils and organic / an organic solvents), that ensures a temperature stability in the range from – 25 °C to + 60 °C (operational temperature range).